Knee replacement

This page is about knee replacement, both total knee replacement and partial knee replacement or resurfacing. It covers what to expect before during and after the surgery as well as the risks and benefits.

“Prompt appointment and really helpful follow up. Communication from Dr Willis-Owen was great, he went out of his way to ensure I was treated as quick as possible. Definitely worth the money to put mind at ease so quickly. Thankyou.

What is knee replacement?

If you are getting severe pain in the knee, with stiffness and difficulty getting around you may well have knee arthritis. Maybe your doctor has already told you that you have arthritis, or you know friends or relatives that have been through it. If you have bad knee arthritis then you may well need to have a knee replacement.

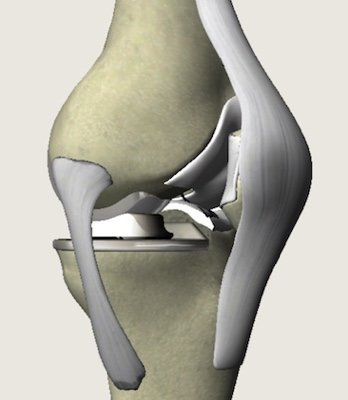

Knee replacements are very sophisticated pieces of metal and plastic designed to mimic the human knee. When your knee is beyond repair I can remove the worn out surfaces and give you new metal and plastic surfaces to get rid of the pain and get back your mobility. Some people refer to a knee replacement as a knee resurfacing. These mean the same thing.

A knee replacement (or resurfacing) improves mobility and reduces pain, although your new knee will not be able to bend quite as far as a good normal knee joint, it will likely be much better than your arthritic knee.

One of the most troublesome aspects of knee arthritis is disturbed sleep. If your walking is severely limited, you are in constant pain, and your sleep is disturbed then you are likely to benefit from a knee replacement. Surgery is usually recommended only if non-surgical treatments, such as physiotherapy and exercise, taking medicines, or using physical aids like a walking stick, no longer help to reduce pain or improve mobility.

Total Knee Replacement

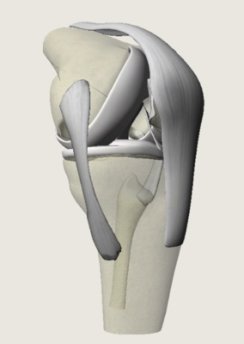

Your knee joint is made up by the ends of your thigh bone (femur), the top of your shin bone (tibia) and your kneecap (patella). These normally glide over each other easily because they are covered by smooth articular cartilage. If your cartilage is worn out or damaged it can make your joint painful and stiff, and the joint becomes inflamed. This is arthritis, and when the pain becomes too much the best treatment may be an artificial knee or joint replacement.

In a total knee replacement I will give you new surfaces on all these parts of the knee, so you are left with none of the surfaces you were born with.

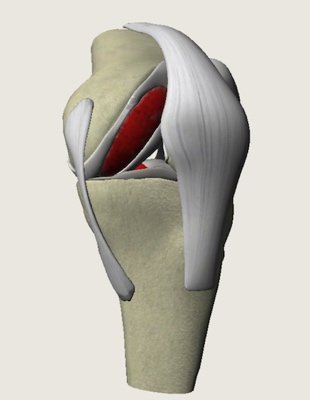

Partial knee replacement – unicompartmental knee replacement

In a lot of people, only one part of the knee is causing trouble. It is usually the inner part (medial) but can be the outer part (lateral) or the knee cap (patello-femoral). In these cases, we can just replace the worn-out part of the knee. This is a partial knee replacement or partial knee resurfacing. It’s also referred to as a uni-compartmental knee replacement because we operate on only one compartment of the knee.

We now know that on average people with partial knee replacements can do more and feel more normal. It is a smaller operation, with smaller risks and better function. Also when the remainder of the knee does wear out it is easier to change than a full knee replacement. The decision between the two is something that you should give careful thought over, and do ask if you have any questions.

Types of Knee replacement

Replacement knee parts are made of a special metal alloy called cobalt chrome and special plastic called ultra-high molecular weight polyethylene. A knee replacement can last for over 20 years in the right conditions.

Not all knee replacements are equal! Many of the designs used in the NHS are based on ideas from 40 years ago and are old fashioned, cheap and associated with quite high levels of dissatisfaction. I am very interested in ‘High-Performance Knee Replacement‘. If you are having knee replacement surgery elsewhere check what sort of knee your surgeon wants to use and why. There are hundreds of different types, some designed a long long time ago and cheap (e.g. PFC and Nexgen) and others much more modern but more expensive that comes in a much wider range of sizes and better shapes (e.g. Persona). The cost of the implant is rarely passed on to you, but the cheaper ones mean someone is making more profit!

Preparing for a knee replacement

I will explain how to prepare for your operation. For example, if you smoke you MUST stop, as smoking increases your risk of getting a chest and wound infection, which can slow your recovery. Losing excess weight can be very beneficial before a knee replacement. It makes the surgery easier and safer and makes the knee replacement last longer. Many people think they will lose weight after their knee replacement, but scientific studies show that this does not usually happen!

The operation usually requires a hospital stay of a few days and it’s done under spinal anaesthesia and sedation. This means you will be asleep during the operation and the bottom half of the body will be numbed. By avoiding general anaesthesia your recovery will be faster and you will typically be sitting out in a chair or walking within hours. You can have a general anaesthetic if you prefer, but this does slow your recovery. Either way, you will be asked to follow fasting instructions. This means not eating or drinking, typically for about six hours before the operation.

I will discuss with you what will happen before, during, and after your procedure, and any pain you might have. This is your opportunity to understand what will happen, and you can help yourself by preparing questions to ask about the risks, benefits, and any alternatives. This will help you to be informed, so you can give your consent for the procedure to go ahead, which you will be asked to do by signing a consent form.

You will be given compression stockings on both legs to help prevent blood clots forming in your veins (deep vein thrombosis, DVT). You will also need to have an injection of an anticoagulant medicine as well as stockings. The injections need to be given every day for 14 days.

What happens during a knee replacement?

A knee replacement usually takes a little under an hour.

I’ll make a single incision down the front of your knee, then remove the worn or damaged surfaces from both the end of your thigh bone (femur), the top of your shin bone (tibia) and your kneecap. I’ll shape the surfaces of your thigh and shin bones to fit the artificial knee joint and then fit the new joint over both bones fixing it in place with a special sort of bone cement.

The wound will be closed with stitches or clips and covered with a dressing. I’ll put a tight bandage on your knee to help minimize swelling.

What to expect afterwards

You will need to rest until the effects of the anaesthetic have passed. You may not be able to feel or move your legs for several hours after a spinal anaesthetic.

You will need pain relief to help with any discomfort as the anaesthetic wears off.

You will have compression stockings on both legs. This helps to maintain circulation. You will be given anticoagulants to reduce the risk of blood clots.

The large bandage around the knee will be taken down at 24-48 hours. The adhesive dressing underneath will appear bloodstained and dirty, but it has been put on in a sterile environment, so it will usually be kept in place for 2 weeks to minimise the risk of infection. At the 2 week stage, the dressing will be removed along with the clips or stitches and the wound should be healed.

A physiotherapist will usually guide you daily through exercises to help your recovery. We will get you up and walking the same day or the next day. You will be in the hospital until you can walk safely with the aid of sticks or crutches. When you’re ready to go home, you will need to arrange for someone to drive you.

Your nurse will give you some advice about caring for your knee and a date for a follow-up appointment before you go home. This will usually be at 2 weeks to take the clips out.

Recovering from knee replacement surgery

You will be provided with painkillers after your surgery. Only take them if you need them. Ice packs and elevation are also helpful. Many patients find that in the hospital with the support of the nurses and physios that they cope quite well, but that the first few days at home can be tough. Be prepared for this, and make sure that your relatives or friends can be there to support you. Don’t be too hard on yourself.

The physiotherapy exercises are a crucial part of your recovery, so it’s essential that you continue to do them for at least two months.

You will be able to move around your home and manage stairs. You will find some routine daily activities, such as shopping, difficult for a few weeks. You may need to use a walking stick or crutches for up to six weeks.

When you’re resting, raise your leg and support your knee to help prevent swelling in your leg and ankle.

Depending on the type of work you do, you can usually return to work after 6 to 12 weeks.

You shouldn’t drive until you are confident that you could perform an emergency stop without discomfort. Typically this is 6 weeks.

“Prompt appointment and really helpful follow up. Communication from Dr Willis-Owen was great, he went out of his way to ensure I was treated as quick as possible. Definitely worth the money to put mind at ease so quickly. Thankyou.

What are the risks?

Knee replacement surgery is commonly performed and generally very safe. However, in order to make an informed decision and give your consent, you need to be aware of the possible side-effects and the risk of complications of this procedure. Overall about 98% of the time things go smoothly. Some of the risks and complications are as follows:

Uncommon:

- Anaesthetic problems

- Infection – this can be a disaster needing months of intravenous antibiotics, possibly changing the knee implant, or very very rarely can end up in amputation. Antibiotics are given after the surgery to prevent this

- Bleeding – rarely needing a blood transfusion

- A scar down the front of the knee that will have a numb patch around the scar. This may take years to improve

- Blood clots (DVT or PE) anticoagulants are given after the surgery to prevent this

- Persistent pain or stiffness, this is usually treated with intensive physio and hydrotherapy, but sometimes needs a manipulation under anaesthesia. This can lead to dissatisfaction

- Wearing out or working loose over the years needing more surgery

- Problems with the kneecap, sometimes needing more surgery

Really rare but really serious:

- Damage to an important blood vessel or nerve – this is very rare but can be very serious and very very rarely can lead to amputation

- Major medical problems and even death! Every year somewhere in the world patients die during or soon after their joint replacement surgery. Because you will have been thoroughly checked before the surgery people who have had joint replacements actually have a lower risk of dying than those who have not!

I will discuss these with you prior to surgery. If you have any questions it may be helpful to note them down to remind you to ask.

Book a consultationFrequently asked questions

It is a treatment for severe arthritis. Most people who have a knee replacement will have pain with walking and will struggle to walk a mile. Their sleep will be disturbed most nights by knee pain, and they will be taking painkillers every day because of the knee. If this sounds like you then and the replacement will probably help you.

This is where a consultation with me should be really useful. We will go through a thorough examination and listen to whereabouts you feel your pain. I will probably get an MRI scan to fully understand the health of your knee. With that information, I will guide you.

A bit like the tyres on your car, it is not a matter of how many years, but how much use. For that reason, knee replacements last longer in slim elderly people than they do in younger people. As a rule, if you have your knee replacement after age 65 it will probably be the only operation you need in your life for that knee.

I see lots of people each year for second opinions where they have had their surgery done elsewhere, and things have not gone well.

Knee replacement surgery is difficult and the outcome depends a lot on the skill of your surgeon. It is a bit more like painting a good portrait rather than assembling flatpack furniture!

If you've got problems with your knee replacement I'll be happy to see you and work out what we can do to get you more comfortable.